Lock products can also be found in many special applications such as roller houses, lifting heaters and lifting lights, as well as internal transport systems. In addition to ventilation and shading in the greenhouse, our drives enable the movement of individual elements in height and on a horizontal level. By using a lifting mechanism, various elements in the greenhouse can be lifted.

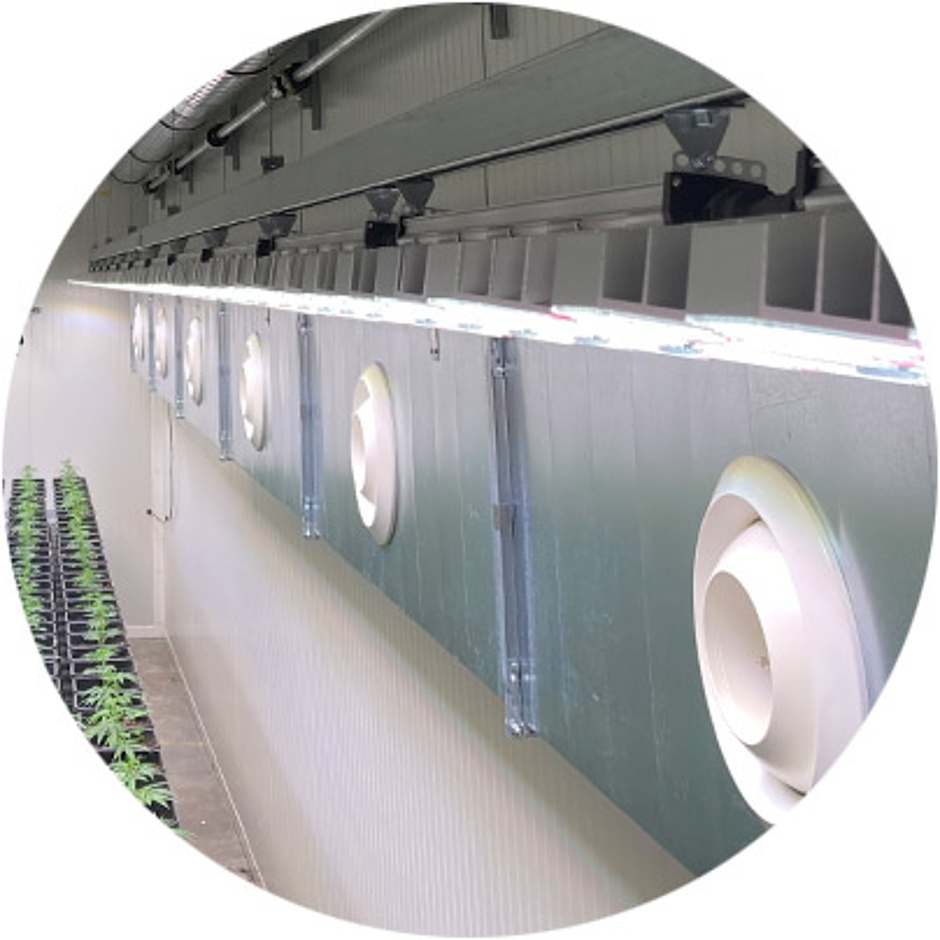

Lift-lower heating

Ideal for efficiently controlling the temperature in greenhouses. Plants with a greater need for heat can experience additional heat by raising the heater vertically with our drive systems.

Why Lock?

As your trusted partner for greenhouse drive systems, we offer cutting-edge technologies and tailor-made solutions for your individual requirements. Our drive systems are characterized by reliability, efficiency and ease of use to ensure that your greenhouse crops receive the best possible conditions for healthy growth.

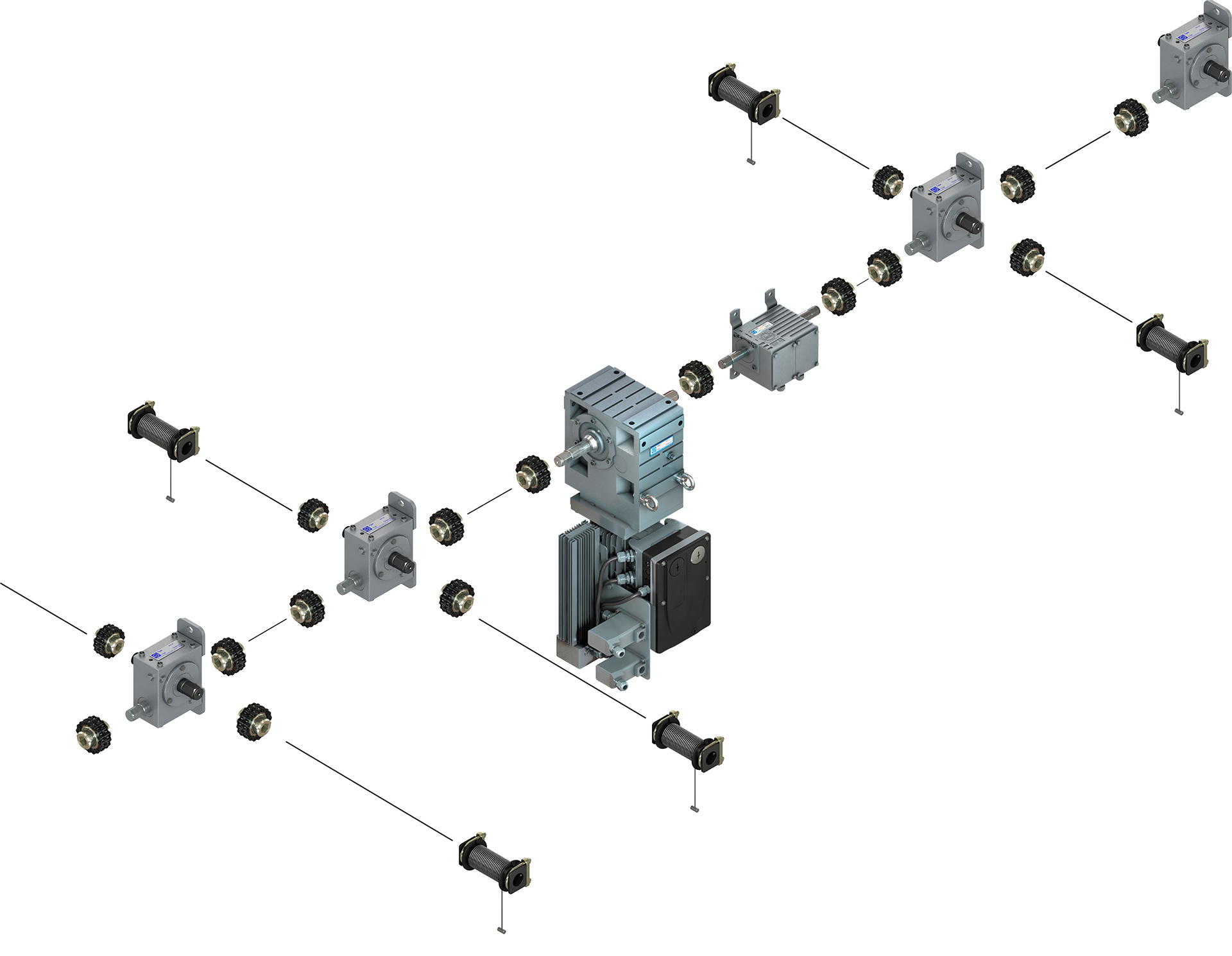

Lifters

Whether you are growing exotic flowers or fruit, without the right lighting, growing plants becomes a difficult undertaking. Lifting lights are ideal for precisely controlling the light to create optimal lighting conditions. The plant lighting is moved using a drive system and deflection gears and cable drums. This allows several lines to be moved individually to create optimal lighting conditions.

Crop lifting system (fruit, cut flowers, vegetables)

Make optimal use of cultivation space in greenhouses

Using state-of-the-art drive technologies, we enable precise movements of the growing beds, allowing height adjustments and inclinations. At the heart of our systems are powerful motors and precise control units that ensure exact positioning of the plant beds. By integrating sensors and automation technologies, our systems can react to environmental conditions and create ideal conditions for crops such as strawberries and ornamental plants.

Largest strawberry greenhouse in North America implemented with Lock

We work closely with our partner company to support greenhouse growers' success in the increasingly competitive strawberry market. Together we have developed a multi-level cultivation system for strawberry production that enables space and efficiency to be optimized through vertical cultivation. This allows more plants to be planted than if the plant were grown at the same height. In Canada, a project covering 18 hectares was realized that now holds the title of the largest strawberry greenhouse built in one piece in North America. In this completely new organic strawberry greenhouse, the plants experience optimal growth thanks to the integrated raising and lowering systems and are optimally exposed to sunlight more than with other systems. This is made possible by the individually adjustable height of the plant tables. In this way, the production and success of greenhouse growers is raised to an even higher level. Multi-level cultivation enables greenhouse growers to increase the number of plants and the products grown.

The lifting systems work in a simple way: the troughs are moved up and down electrically as required using specially optimized drives from Lock. The self-locking mechanism ensures safe operation over the entire service life. This is achieved by the unique double worm gear in the gear box of the Lock drive.

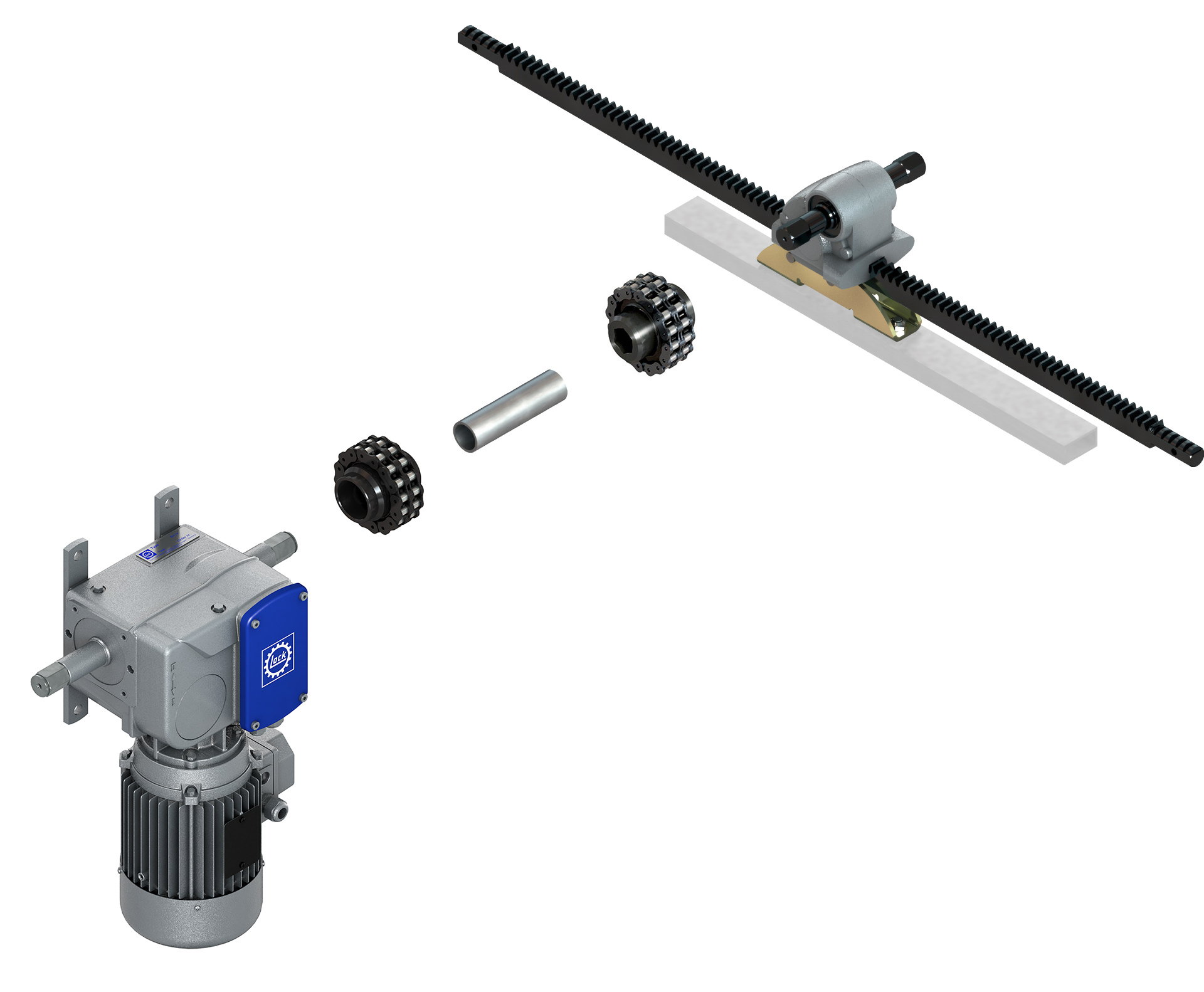

Linear adjustment

For the automation of production, whereby different cultures can be moved in troughs or tables.